NO RED RUST SPOTS!

HIGH-PERFORMANCE ORGANIC COATING BY EFFCO

Zinc flake corundum technology is a revolutionary coating process that has been developed to provide superior corrosion protection for metal surfaces, provide protection against corrosion, enhance their durability, improve their performance, prevent rust, increase resistance to chemicals, and reduce friction during installation.

There is a need to find non-toxic alternatives compatible with current industrial techniques. Due to environmentally friendly paint formulations and less environmental pollution, our coating technology is far superior and user-friendly compared to the existing metal finishing coating systems.

We truly believe in manufacturing environmentally friendly new-generation corrosion protection technology which replaces the polluted electroplating mechanism thereby stopping the discharge of the pollutants.

Zinc flake corundum technology is ideal for use in a wide range of applications, including automotive, aerospace, marine, and industrial applications.

SUPERIOR CORROSION PROTECTION!

LONG- LASTING RESULTS

ZINC-FLAKE COATING

Independent specialist with over 15 years of experience in zinc-flake coating and many more. We take care that our zinc-flake coating is exclusive of the best and strictly controlled quality and is prepared individually for each product. Go ahead and upgrade corrosion resistance performance even for the smallest components and help to reduce costs due to material failure. Otherwise, they risk compromising the integrity of the entire system or structure. This process contains many benefits:

- Resistant to extreme temperature variations

- Friendly to the environment

- Electrically conductive

- Broader versatility for parts of different shapes, sizes, and geometries with options for varying layer thicknesses

- Better protection against hydrogen embrittlement

- Environmentally friendly and there is no risk of any hydrogen embrittlement for high-strength fasteners

We have already adviced offshore projects, automotive applications, onshore construction, chemical plants to increase lifetime. Contact our specialist M. Wirken for your project!

ECOMET WATER REDUCTIBLE TOPCOAT SERIES

EFFCO Fastener Coating Products as per ISO-10683/ASTMF-1136

ECOMET TOP SILVER

Water reducible hydrophobic topcoat sealer for base coats like ECOMET 500, Zinc plating and other zinc-based surfaces. The coating is applied by dip sin or spray followed by curing into oven for 200 deg c 25 mins.

ECOMET TOP GREEN

Water reducible hydrophobic topcoat sealer for base coats like ECOMET 500, Zinc plating and other zinc-based surfaces. The coating is applied by dip sin or spray followed by curing into oven for 200 deg c 25 mins.

ECOMET TOP COPPER

Water reducible hydrophobic topcoat sealer for base coats like ECOMET 500, Zinc plating and other zinc-based surfaces. The coating is applied by dip sin or spray followed by curing into oven for 200 deg c 25 mins.

ECOMET TOP BROWN

Water reducible hydrophobic topcoat sealer for base coats like ECOMET 500, Zinc plating and other zinc-based surfaces. The coating is applied by dip sin or spray followed by curing into oven for 200 deg c 25 mins.

FEATURES

- Environmental Friendly Coating

- Protective & Performance Coating

- Cost-effective and superior corrosion protection system

- Water reducible- transparent topcoat sealer

- Technological association with expertise Europe & USA

- Well equipped inhouse R&D centre

- Excellent coverage

- Avoiding landfilling and scraping

- Over 15+ Years of sustainable business history

- Over 2000-6000 hours SST

- Over 60+ Plant & Equipment Installations worldwide

- Local know-how & technical support

HIGHLY EFFECTIVE AND INNOVATIVE!

ECOMET WATER REDUCTIBLE COATING SERIES

EFFCO Fastener Coating Products as per ISO-10683/ASTMF-1136

ECOMET

500

Water reducible nano zinc aluminium flake chrome VI free coating for anti-corrosive application by dip spin or spray. The coating comes with A, B and C as a 3-pack system. It needs to mix before application by dip spin or spray. Curing temperature is 330 deg c for 30 mins

ECOMET TOP SILVER

Water reducible hydrophobic topcoat sealer for base coats like ECOMET 500, Zinc plating and other zinc-based surfaces. The coating is applied by dip sin or spray followed by curing into oven for 200 deg c 25 mins.

ECOMET TOP BLACK

Water reducible hydrophobic topcoat sealer for base coats like ECOMET 500, Zinc plating and other zinc-based surfaces. The coating is applied by dip sin or spray followed by curing into oven for 220 deg c 25 mins.

ECOMET TOP CLEAR

Water reducible hydrophobic topcoat sealer for base coats like ECOMET 500, Zinc plating and other zinc-based surfaces. The coating is applied by dip sin or spray followed by curing into oven for 150 deg c 25-30 mins.

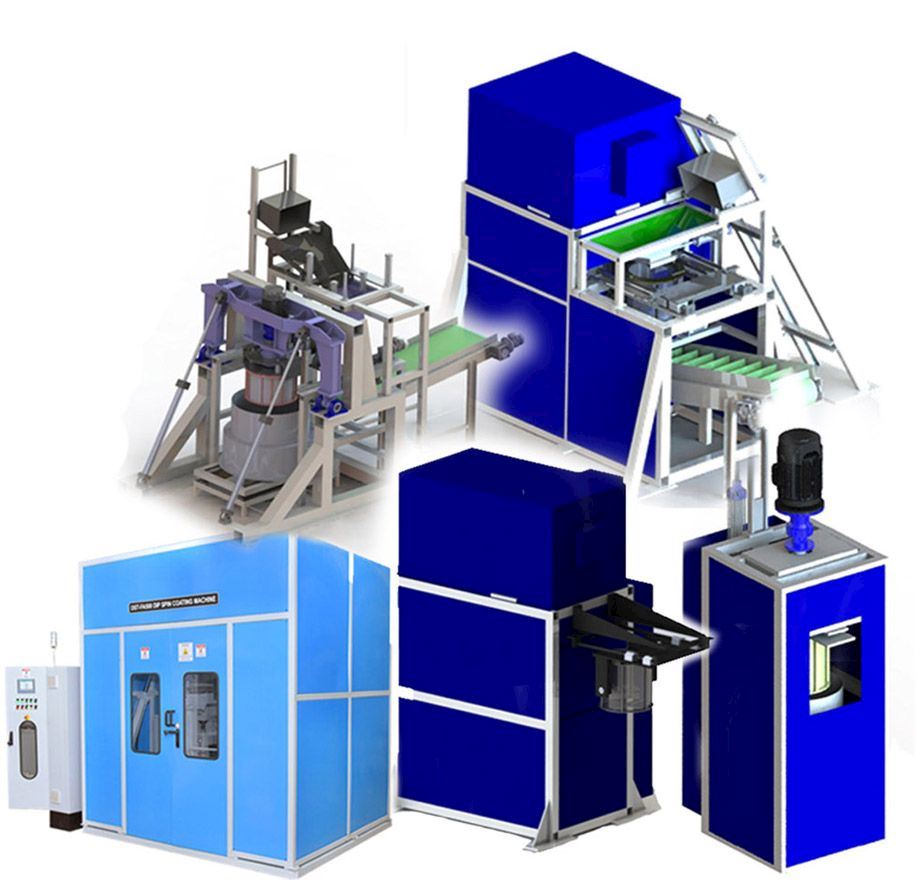

DIP-SPIN COATING MACHINES

New generation simplified Automatic dip spin coating application equipment technology. Mechanically applied Dip Spin coating, you can coat a variety of fasteners, sheet metal parts, springs, various threaded hardware, etc.

These machines are worth using for a variety of reasons:

- Efficiency: Dip spin coating is an efficient method for coating large quantities of fasteners quickly and consistently. The process involves immersing the fasteners in a coating solution and then spinning them at high speeds to evenly distribute the coating.

- Uniform Coating: The spinning motion of the dip spin process helps to ensure that the coating is applied uniformly to all surfaces of the fastener. This ensures that the coating provides complete coverage and protection to the fastener.

- Cost-effective: Dip spin coating is a cost-effective method for coating fasteners, as it can be done in large batches, with minimal labor and material costs.

- Wide range of coatings: Dip spin coating can be used with a wide range of coating materials, including zinc, phosphate, and polymer coatings. This makes it a versatile option for fastener coating.

- Corrosion resistance: The coating applied through the dip spin process provides excellent corrosion resistance, which is essential for fasteners used in outdoor or harsh environments.

Order from the range of these machines: Dip Spin Coating Machine – Model DS 200, Model DST 250 with Tilting, Model DS 250, Model DST 300, Model DST 400, Model DST 500, Model DST 500-AL, Model DST600, Model DSP 450-semiauto-For water base coating, Degreasing Unit- with Washing & Drying Chamber, Curing Furnace – 22 meters long, Curing Furnace 13 meters long.

ECOMET SOLVENT BASE COATING SERIES

EFFCO Fastener Coating Products as per ISO-10683/ASTMF-1136

ECOMET CORUNDUM

Zinc and Aluminium Flakes combined with Corundum and other nano crystal carbon material to form never fail thin film. The coating is single pack, ECOMET solvent is require adjusting viscosity. The coating is applied by dip spin or spray method followed by curing in over at 220 deg c 25 mins.

ECOMET Titanium CDG

COLD DIP GALVANISING the alternative to Hot Dip galvanising (HDG) this product has Zinc and nano crystal carbon based raw material to form 60-80 microns thickness for threaded hardware. The coating is applied by dip spin or spray method followed by curing at 220 deg c 25 mins. This is ideal alternative for HDG and mechanical galvanizing.

ECOMET SOLVENT

This is a solvent to be used for adjusting viscosity of ECOMET CORUNDUM and ECOMET CDG products.

REDUCE LABOR COSTS

The next generation Zinc-Flake coating. Zinc and Aluminium Flakes combined with Corundum and other nano crystal carbon material to form never fail thin film. The coating is single pack, ECOMET solvent is require adjusting viscosity. The coating is applied by dip spin or spray method followed by curing in the oven.

Known Coatings, Platings & Finishes for fasteners are: Anodizing Aquaphos Barrel & Rack Options Bead Blasting Black Organic Black Oxide Black Tech Bright Nickel Bright Dip Cadmium C.A.R.C. Chrome Chrome-Free Coatings Chrome-Free Post Treatments Color Chromating/Dyes Copper Corundum-Zinc Lamellar Custom Masking Delta Protekt Dry Film Lubricants Ecomet E-Coat Electroless Nickel Electroless Zinc Electro-Polish Epoxy Paint Fluorocarbon Galvanize Geomet Gold Hot Dip Galvanized Magni Magni / DorrItech Manganese Phosphate Mechanical Galvanized Mechanical Zinc Metkote Metric Blue Nickel Olive Drab Paints/Color ID Passivation (commercial, aerospace) Phosphate Phosphate & Oil Phosphatizing Pickling/Cleaning Polymer coat PolySeal Powder Coat PTFE/Fluorocarbon Rust proofing Sealants Sharperizing Shot Peening SiCOAT Silver Teflon Texacote Texacote/ Aquaphos Tin Wax Xylan Zinc Electroplated Zinc Iron Zinc Nickel Electroplating Zinc Phosphate Thermal diffused zinc ( sherardizing), Aluminizing, Japaning, Aluminum ceramic, Nano-galv, Wet Galvanizing, Organic coating, CDG-cold dip galvanising, Torque control film.